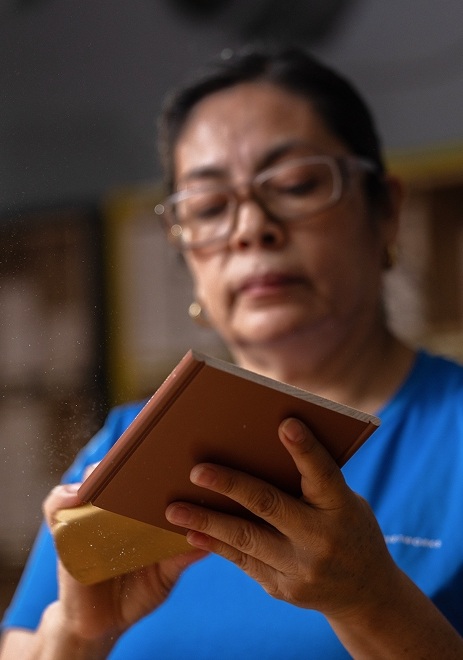

Updating the pour-down process improves color accuracy in cabinetry by providing a more consistent and uniform application of color or finish, resulting in:

Training will be delivered directly from our manufacturer partner, providing insight and guidelines for using the finish. This will positively impact quality, efficiency, consistency, and, most importantly, improve the final result of the process. This requirement will enhance:

Not all humans see color exactly alike. By creating and requiring a "color test,” we are essentially calibrating our auditors. This helps:

Exceptional "Finish Master Standards" is our target. It will take more than tools and process improvements — it will also require constant measurement and monitoring. Our controlled and measured process will outline:

Quarterly finish reviews will be conducted at all producing sites to ensure color accuracy and alignment. This step is the formalized process that ensures our finish process and parameters. It creates:

Please revisit this page for further updates and details regarding our process improvements.

Coming Soon

Marketing Materials

Upgrade